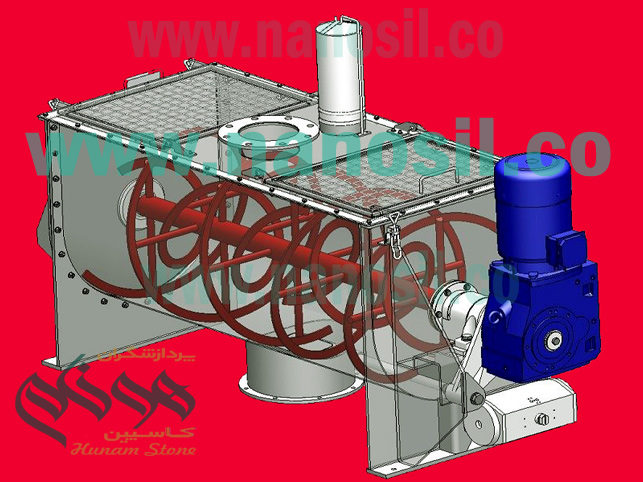

Types of single-use mixer dough tile adhesive, concrete adhesive ribbon blender design:

Static ribbon mixer with a special steel body for dough adhesive with a capacity of 100 kg along with a 4-inch exit valve

Static ribbon mixer for making dough adhesive with a capacity of 200 kg

Static ribbon mixer, manufacture and production of dough tile adhesive with a steel body with a capacity of 300 kg

Static ribbon mixer, for the production of dough tile adhesive with the capacity 400 kg

The body used in all the above mixers is 6 mm (With the ability to upgrade the thickness according to the applicant's request),

mechanical or pneumatic 4-inch butterfly valve, the distance from the floor to the adjustable valve is.

The possibility of making ribbon mixers with the desired capacity to provide the applicant. Types of single-use mixer powdery tile adhesive (and filler powder):

Types of single-use mixer powdery tile adhesive (and filler powder):

Ribbon mixer of powdery tile adhesive with Normal body horizontal sheets and with capacity of 200 kg

Horizontal ribbon mixer for the production and manufacture of powdery tile adhesive, filler powder and grout and... with a capacity of 300 kg

Horizontal ribbon mixer for producing powdered adhesive with a capacity 400 kg The body used in 6 mm powdered ribbon mixers (up-gradeable according to the applicant's request), with the exit valve in the form of mechanically and with ability to adjust the height of the floor to the exit valve.

The body used in 6 mm powdered ribbon mixers (up-gradeable according to the applicant's request), with the exit valve in the form of mechanically and with ability to adjust the height of the floor to the exit valve.

It is possible to make horizontal ribbon mixers according to the specifications and weights required by the applicant.

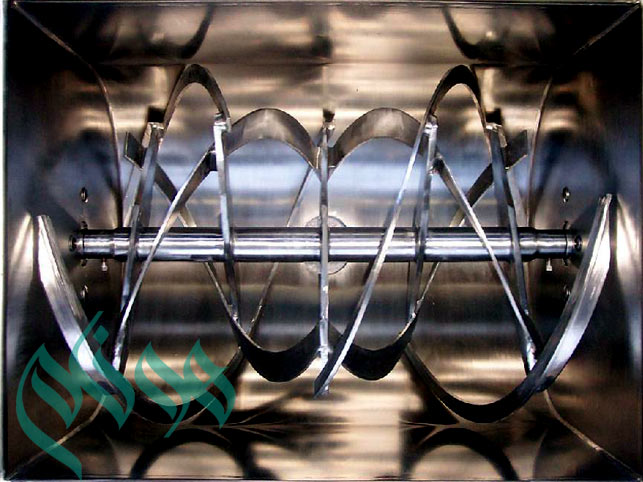

Images of Ribbon Mixers for the production of various tile adhesives and building adhesives:

* Note: According to various experiences in the field of mixers, from the HUNAM company group to the dear applicants for the purpose of making the dough and powder tile adhesives from the PAN design mixers listed below, for the following reasons use.

* Note: According to various experiences in the field of mixers, from the HUNAM company group to the dear applicants for the purpose of making the dough and powder tile adhesives from the PAN design mixers listed below, for the following reasons use. Ribbon mixers have a lower mixing power than the PAN design mixers.Therefore, assuming that the raw materials are loaded in the ribbon mixers, the mixing time of the materials in the ribbons mixer of powdered adhesive is between 20 to 30 minute sand in the ribbon mixers for dough adhesive is 30 to 60 minutes. Therefore, by adding special specification, this time can be reduced by about 30%.However, the advantage of using PAN's design mixer and addition arm, duration of mixing materials for dough and powdery adhesives assuming the raw material is loaded, it is about 10 to 12 minutes long which is a sign of the power of mix and high mixing speed.

Ribbon mixers have a lower mixing power than the PAN design mixers.Therefore, assuming that the raw materials are loaded in the ribbon mixers, the mixing time of the materials in the ribbons mixer of powdered adhesive is between 20 to 30 minute sand in the ribbon mixers for dough adhesive is 30 to 60 minutes. Therefore, by adding special specification, this time can be reduced by about 30%.However, the advantage of using PAN's design mixer and addition arm, duration of mixing materials for dough and powdery adhesives assuming the raw material is loaded, it is about 10 to 12 minutes long which is a sign of the power of mix and high mixing speed. For the production of dough adhesives, vertical ribbon mixers and for the mixing of powdered adhesive materials, we recommend horizontal ribbon mixers. in this case, you will need two mixers to produce dough adhesive and powdered adhesive.If in our proposed PAN's design mixers, you can create both types of glue (powder and dough types) with just one mixer, in which case you will have a great deal of savings in the number of mixers.The only prerequisite for the production of two types of adhesives is the proper cleaning of the mixer with a car wash prior to generating a new type of adhesive.

For the production of dough adhesives, vertical ribbon mixers and for the mixing of powdered adhesive materials, we recommend horizontal ribbon mixers. in this case, you will need two mixers to produce dough adhesive and powdered adhesive.If in our proposed PAN's design mixers, you can create both types of glue (powder and dough types) with just one mixer, in which case you will have a great deal of savings in the number of mixers.The only prerequisite for the production of two types of adhesives is the proper cleaning of the mixer with a car wash prior to generating a new type of adhesive. The price of PAN's design mixers is much more suitable than ribbon design mixers.

The price of PAN's design mixers is much more suitable than ribbon design mixers. Following are the technical specifications of some dough and powdered tile adhesive mixers (designed by PAN) it is noted:

Following are the technical specifications of some dough and powdered tile adhesive mixers (designed by PAN) it is noted:

PAN's design mixer of doughy and powdery tile adhesive - Tile adhesive powder 250 to 300 kg and doughy adhesive 180 to 220 kg - Multi-use mixer

Three-horsepower electric engine and high-quality gearboxes 90,and special 28 mm centrifugal arms with adjustable arm,the thickness of the floor sheet is 10 mm and the thickness of the wall sheet of the mixer is 6 mm,the mixer has a manual exit part of material with a radius of about 30 cm with bearings, portable machine with cast iron 13, the size of the machine with a capacity of 450 liters,The capacity of making 220 kg of doughy adhesive and 300 kg powdery adhesive according to the formulation and material meshing, the diameter of 110 cm and the height of the body of the mixer is 50 cm, with 2 mm hinged bonnet (two pieces) and additive hopper / 4 main arms and blades and two additional blades to increase the strength of the mix.

Mixer of Doughy and Powdery Tile Adhesive (PAN's design) - 450 kg powder tile adhesive and 380 kg dough adhesive:

5.5-HP three-phase electric engine (made by YILMAZ Turkey) and gearbox 130,and special 33 mm centrifugal arms with ability to adjustable arm, the thickness of the floor sheet is 10 mm and the thickness of the wall sheet of the mixer is 6 mm,the mixer has a manual exit part of material with a radius of about 33 cm with bearings, portable machine with cast iron 13, the size of the machine with a capacity of 700 liters, The capacity of making 350 kg of doughy adhesive and 400 kg powdery adhesive according to the formulation and material meshing, with 2 mm hinged bonnet (two pieces) and additive hopper / 5 main arms and blades and two additional blades to increase the strength of the mix, the diameter of 130 cm and the height of the body of the mixer is 55 cm.

Mixer of Doughy and Powdery Tile Adhesive (PAN's design) - 750 kg powder tile adhesive and 600 kg dough adhesive:

-7.5-HP three-phase electric engine (made by YILMAZ Turkey) and gearbox 150, and special 33 mm centrifugal arms with ability to adjustable arm, the thickness of the floor sheet is 15 mm and the thickness of the wall sheet of the mixer is 6 mm, the mixer has a manual exit part of material with a radius of about 33 cm with bearings, portable machine with cast iron 16, the size of the machine with a capacity of 850 liters, The capacity of making 520 kg of doughy adhesive and 600 kg powdery adhesive according to the formulation and material meshing, with 2 mm hinged bonnet (two pieces) and additive hopper / 5 main arms and blades and 3 additional blades to increase the strength of the mix, the diameter of 140 cm and the height of the body of the mixer is 55 cm.

Mixer of Doughy and Powdery Tile Adhesive (PAN's design) - 1000 kg powder tile adhesive and 900 kg dough adhesive:

-10-HP three-phase electric engine (made by YILMAZ Turkey) and gearbox 150, and special 33 mm centrifugal arms with ability to adjustable arm, the thickness of the floor sheet is 16 mm and the thickness of the wall sheet of the mixer is 8 mm, the mixer has a manual exit part of material with a radius of about 33 cm with bearings, portable machine with cast iron 16, the size of the machine with a capacity of 1100 liters, The capacity of making 850 to 900 kg of doughy adhesive and 900 to 1000 kg powdery adhesive according to the formulation and material meshing, with 3 mm hinged bonnet (two pieces) and additive hopper / 6 main arms and blades and 4 additional blades to increase the strength of the mix, the diameter of 160 cm and the height of the body of the mixer is 55 cm.

Mixer of Doughy and Powdery Tile Adhesive (PAN's design) - 1500 to 1600 kg powder tile adhesive and 1300 to 1400 kg dough adhesive:

-15-HP three-phase electric engine (made by YILMAZ Turkey) and gearbox 185, and special 33 mm centrifugal arms with ability to adjustable arm, the thickness of the floor sheet is 15 mm and the thickness of the wall sheet of the mixer is 8 mm, the mixer has a manual exit part of material with a radius of about 35 cm with bearings and manual gearbox, the size of the machine with a capacity of 1500 liters, The capacity of making 1300 to 1400 kg of doughy adhesive and 1500 to 1600 kg powdery adhesive according to the formulation and material meshing, with 3 mm hinged bonnet (two pieces) and additive hopper / 7 main arms and blades and 5 additional blades to increase the strength of the mix, the diameter of 180 cm and the height of the body of the mixer is 60 cm.

Mixer of Doughy and Powdery Tile Adhesive (PAN's design) - 2700 to 300 kg powder tile adhesive and 2200 to 2400 kg dough adhesive:

-30-HP three-phase electric engine (made by YILMAZ Turkey) and gearbox 210, and special 33 mm centrifugal arms with ability to adjustable arm, the thickness of the floor sheet is 20 mm and the thickness of the wall sheet of the mixer is 8 mm, the mixer has a manual exit part of material with a radius of about 35 cm with bearings and pneumatic Jack with added key, with two-pieces water trap and pressure control and electric valve, the size of the machine with a capacity of 2110 liters, the capacity of making 2200 to 2400 kg of doughy adhesive and 2700 to 3000 kg powdery adhesive according to the formulation and material meshing, with 4 mm hinged bonnet (three-pieces) and additive hopper / 8 main arms and blades and 6 additional blades to increase the strength of the mix, the diameter of 196 cm and the height of the body of the mixer is 700 cm.

* The necessary condition for the use of PAN layout mixers compared to Ribbon pasty mixers is that: In the ribbon mixers, first of all fluid is loaded in the mixer, and then the powders, in the event that, in the PAN mixer first of all powders are loaded and then the liquids are added.