In addition to producing various types of building adhesives, manually, automation and automation lines can also be considered for the production of various tile and construction adhesives. but before any work should production capacity, formulation type, more or less automation to be determined, and based on need and according to the amount of funding automation and semi-automatic production lines for building adhesives be designed.

Because of the high diversity of materials and solids, also the Variation of liquids and the difference in the viscosity of building adhesive additives, the way they measure and load will vary.

Even depending on the type of packaging of final product, part of the transferor and ... is changed. in some cases, it may request the applicant, single-product line or multi-product line that should be in accordance with the policy of product production specific changes in the production line are considered until for production be suitable for multi-product.

in the following only two cases from designed automation production line it's noted:

in the following only two cases from designed automation production line it's noted:

example one: powdered and pasty Tile Adhesive Mixer PAN design | Powdered Tile Adhesive 750 Kg 600 Kg Pasty Adhesive:7.5 HP three-phase motor 900 rpm with gearbox 150 Custom, and special 33 mm centrifugal arms with adjustable arm, the thickness of the floor sheet is 15 mm and the wall thickness of the mixer is 6 mm, has a part exit materials manually with a radius of 33 centimeters with bearings, the size of the device with a capacity of 850 liters,The capacity of making 520 kg of pasty adhesive and 600 kg powder adhesive according to the formulation and meshing materials,with 2 mm hinged blind two-piece and additive hopper, 5 arm and main blade and 2 additional blades to increase the power of the mix, the diameter of the mixer is about 140 cm and the body height of the mixer is 55 cm.

Multi-user and shared packaging system | Screw piped packaging of powdered adhesive & pasty adhesive in the form of an angle |

8 inch screw packing system with 2.5 inch Mannesmann Tube and a 4 mm blade,4-horsepower engine and gearbox, a 700 kg hopper with a sheet of 3 mm,With the bonnet and hinge,Body length and Shooting 5 meters, along with the butterfly gate and Jack 63 * 125 and pneumatic accessories,Pneumatic pedal, large pressure control electric valve, key and…

Example two:pasty and powder tile adhesive mixer designed by PAN | powder tile adhesive 1500 to 1600 kg and pasty adhesive from 1300 to 1400 kg | 15 HP three-phase motor 900 rpm with custom gearbox 185, and special 50 mm centrifugal arms with adjustable arm,Thickness of the floor sheet 20 mm and the wall thickness of the mixer is 8 mm, has an exit part manually with a radius of 35 cm with bearings and manual gearboxes, the size of the machine with a capacity of 1500 liters,Capacity of making from 1300 to 1400 kg of pasty adhesive and 1500 to 1600 kg powdered adhesive according to the formulation and meshing materials,with hinged bonnet 3 mm two-piece sheet, 7 arm and main blade and 2 additional blades to increase the strength of the mix and the diameter of the mixer is about 180 cm and the height of the mixer body is 60 cm

along with 4 base with a height of 220 cm 14*14 and the top of the sheet for the foundation

casting system piping for packing powder adhesive in edge pocket| 6 inch screw packing system with 1.5 inch Mannesmann Tube and a 4 mm blade, 4-horsepower engine and gearbox, Output terminal with 2.5-inch screw for casting of edge pocket, the hopper has a size of 1500 kg with a sheet of 3 mm, with lid and hinges,Screw body length 3 m,with the inverter related to the connect and disconnect key

Screw loaded raw materials inside the solid-loaded mixer | Hopper load volume of 300 liters,with 8-inch screw with 2.5 inch Mannesmann Tube, under an angle of 60 degrees to a length of 6.5 meters with an output of angle 50 centimeters, with a 5.5 horsepower engine and a respective gearbox 100 rpm with gear and chains, with pendant bearings, and two bases for fixing the system and respective key

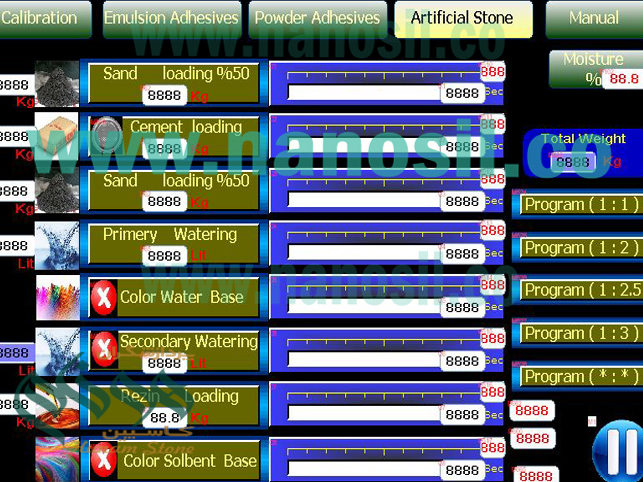

Central control panel | machine control panel, Protective control, inverter, and respective key and putting the wait for the future