Equipment of production line artificial Facade & Floor Tile stones machinery (nano cement plast artificial stone production line ) with the capacity of 180 to 220 square meters per shift, including all required machines and following items

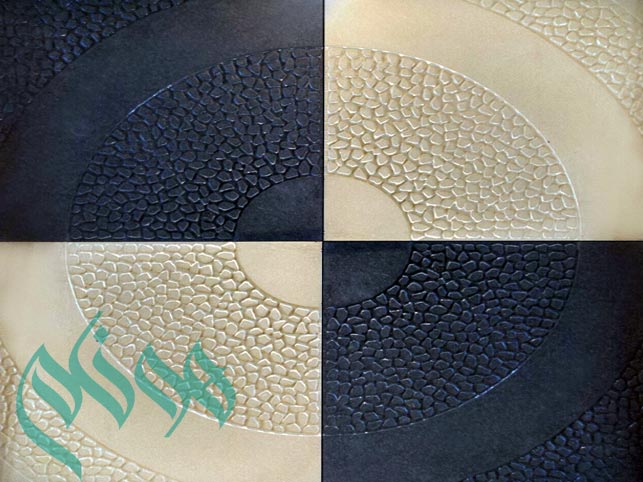

& Different Specifications Manual Production Machine; For Produce, Nano Cement Plast Artificial Façade Stone, Flooring Mosaic Tile, Paving, Step Artificial stone, Decorative artificial stone, Special Design Stone Building, GFRC Artificial Stone, Also with the ability to produce various types of building adhesives, Tile adhesive Powder & Pasty (20 Types Of Building Adhesives Product) & .etc

*Up gradable manual cement plast Artificial Stone Production Line, in the finally can be upgarde to Semi-Automatic Or Automatic Artificial Stone Production with Produce capacity 350-400 SQM Per Shift

The vertical vibration machine (for nano cement plast artificial stone) with the area of 6 square meters (2x3 M), with two Vibrator motors 1300 Kg, 8 mm anti-wear sheets, with European central wide wing chassis and carriage cargo, special metallurgy springs, and the aerodynamic surfaces

The vertical vibration machine (for nano cement plast artificial stone) with the area of 6 square meters (2x3 M), with two Vibrator motors 1300 Kg, 8 mm anti-wear sheets, with European central wide wing chassis and carriage cargo, special metallurgy springs, and the aerodynamic surfaces

Pan design centrifugal mixing machine (for manufacturing of artificial stones, nano cement plast facade and floor stones and building adhesives and additives), with 15 hp electro-motors ( iylmaz motor ) 900 rpm , and custom 185 gearboxes solar, special 35 mm centrifugal blades with adjustable arms and anti-wear Hard sheets (15 mm for floor and 8 mm for body ) with one manual outlet part of materials, large gear steel screw gearbox (from bottom), portable device, the machine with 900 liters capacity and current mixing capability of 450 kg normal-weight materials (nano cement plast main formula), current mixing capacity of light-weight materials similar to 800 kg normal weight materials and the capacity of adhesives production up to 1000 kg

Pan design centrifugal mixing machine (for manufacturing of artificial stones, nano cement plast facade and floor stones and building adhesives and additives), with 15 hp electro-motors ( iylmaz motor ) 900 rpm , and custom 185 gearboxes solar, special 35 mm centrifugal blades with adjustable arms and anti-wear Hard sheets (15 mm for floor and 8 mm for body ) with one manual outlet part of materials, large gear steel screw gearbox (from bottom), portable device, the machine with 900 liters capacity and current mixing capability of 450 kg normal-weight materials (nano cement plast main formula), current mixing capacity of light-weight materials similar to 800 kg normal weight materials and the capacity of adhesives production up to 1000 kg

Central devices control panel :device control panel, with electrical protective for relevant electro-motors, with detection system of temperature (heat) and time of making polymeric materials and compounds, with the relevant accessories

Central devices control panel :device control panel, with electrical protective for relevant electro-motors, with detection system of temperature (heat) and time of making polymeric materials and compounds, with the relevant accessories

Training the technical knowledge of manufacturing products along with training workshops and offering specific formulations including following items

- Initial training: including a 5-day workshop of artificial stone and nano cement plast technology transfer at the office of Hunam Stone Company

- Secondary training: after receiving initial training and presented booklets, customers are responsible for supplying raw materials, molds and relevant equipment ; and based on existing conditions and pre-coordination, applicants will be announced about the second training part. The second training will take 2-3 days at the project site Providing technology of manufacturing cement plast products including formulation of polymeric materials and nano products, according to the results of the raw materials, soil and concrete analysis, weather conditions and the type and color of products (temperature, humidity, etc.);

Providing technology of manufacturing cement plast products including formulation of polymeric materials and nano products, according to the results of the raw materials, soil and concrete analysis, weather conditions and the type and color of products (temperature, humidity, etc.);

and the standards and methods of raw materials analysis by means of very simple equipment ,etc. Learning about additives to control of polymeric reactions based on different geographical conditions, tile production technology;

antique mosaics and flooring and various facades; multi components products with high color range and method of producing different colors according to the customer’s demand; methods of creating laminate over the artificial stone surface, simulation of natural stones(marble, granite and travertine);

producing formulation of normal volume density(2200 kg per cubic meter), medium-weight(1500-1700 kg per cubic meter),light-weight (1100 kg per cubic meter) and ultra-light-weight(800-1000 kg per cubic meter);

Training the knowledge of specific products in this field, transfer ring work experiences and know ledge of production, related to the assigned products in contract, in order to prevent subsequent losses and errors due to the lack of experience of the new applicants;

offering important points to the customers to improve marketing performance ; consulting applicants in the field of selecting best sellers molds according to the taste of applicants along with providing all the relevant documents and producing formulation, and contract of starting up and supplying the required raw materials for unlimited time Training and formulation of more than ten different applicable products in ceramic and artificial stone industries (and the technology of building adhesives) ready-to-use dough adhesives with different costs (in two main categories from normal to special ones), powder adhesives in various types and in two main categories, training the knowledge of building primers for plaster walls (used in stone installing process, building paintings and anti-scurf and water proof primers);

Training and formulation of more than ten different applicable products in ceramic and artificial stone industries (and the technology of building adhesives) ready-to-use dough adhesives with different costs (in two main categories from normal to special ones), powder adhesives in various types and in two main categories, training the knowledge of building primers for plaster walls (used in stone installing process, building paintings and anti-scurf and water proof primers);

concrete adhesive for more adhesion formation and elasticity properties; supplement of powder adhesives and adhesives for installation of lightweight concrete in two different types; sealing dough for using in bathrooms ;colorful joint powder, anti-bacterial joint powders; building and industrial grouts in several different types and combinations with high adhesion strength;

very low cost production technology of rough stones with positive and negative angles for interior designs applications (and cellulose and antique coatings); formulation of shiny and matte resin for waterproofing of natural and artificial stones in addition to luminescent, anti-oil and anti-UV resin formulations | with contract of supplying required raw materials for unlimited time and after sales service Training and formulation of more than ten chemical building additives and building

Training and formulation of more than ten chemical building additives and building

products along with long-period after sale service

Training and transferring innovative techniques of painting and installing laminates over the stone surface with different methods (special techniques) for interior and exterior building decoration with very specific colors and value-added product in theoretical and practical sessions; frequent training and other services to learn new techniques in the future in person & distance

Benefits of upgradable production line Artificial Stone

Benefits of upgradable production line Artificial Stone

Suitable for preparing artificial stone workshops and production lines with perfect capacity of 150 to 200 square meters per shift

Launching in the shortest time and with minimum required capital

Upgrade to higher technology and automatic production lines by adding advanced equipment

Capable for producing highly diversified technologies and products in the field of building industry by means of available and relevant machines

Disadvantages of upgradable production line Artificial Stone

Operators are responsible for detection of chemical and polymeric reactions and determining sufficient dose of materials consumption, therefore the quality of products is directly related to the accuracy of operator; and in the condition of operating with required accuracy, high quality of products will be produced

Raw materials loading should be manually done by operators (based on traditional way); as a result, production capacity will be directly related to the personnel energy

The relatively low production volumes compared to automatic and semi-automatic production lines