Introduction:

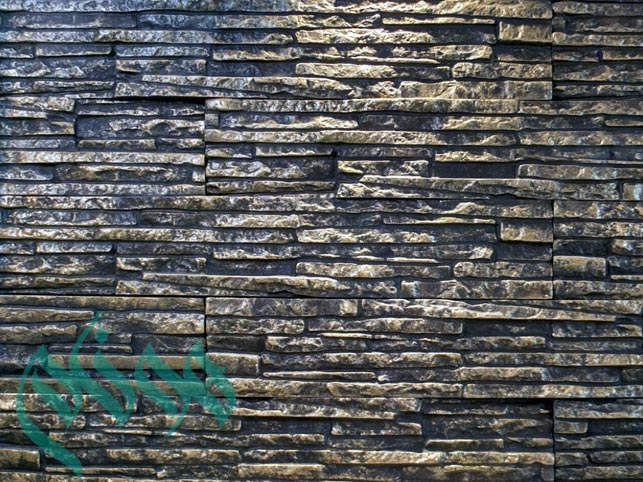

This research was done in 136 hours in the company Which is not part of HUNAM artificial stone company and lasted 1 month. The purpose of this research was to identify the bottlenecks of the company, the problems of the production of artificial stone cement plast and the elimination of them.The purpose of this research is to give your loved ones the possibility of these problems in your company.Very simple problems that may cause significant damage to the company and the artificial stone products produced by us, and by providing this information (simple), we will protect you from falling into the trap of these problems.

Our goal is honesty in providing modern building services and satisfying each one of your loved ones.

Research methodology:

The study was completed within two weeks of objective observation.

During this time, data collection, problem identification, and written.

Four days were spent to complete observations and provide solutions.

At the end of the twentieth day, the company was presented with problems as well as suggestions to improve the status quo and bring it to a favorable position.

Estimated project duration was considered to be 10 days, which was monitored by the researcher of the project, and at the end of the month, identified bottlenecks were eliminated as far as possible. Analysis phase:

Analysis phase:

At first, it focuses on identifying existing problems (in terms of increasing productivity) and, finally, providing solutions.

Productivity has a simple concept: the relationship between the output of an organization and the inputs it needs.

We can determine the amount of productivity by dividing the inputs into inputs. We can also increase productivity by improving this ratio, which means we can squeeze out more or better with a certain amount of inputs.

One of the methods that is effective in improving productivity is the use of a common quarrel in the factory. This means that for the constructive comments, the reward was considered. Perhaps this seems useless at first glance, and it's easy to say how simple a worker can do, but it should be noted that the factory is made up of the same people, and if any person can even solve a very simple problem in his or her field, Yes, the overall productivity of the factory will increase incredibly.

It also attracts the attention of the workers in the production and packaging sector and makes them more active and makes them afraid of giving the idea as simple as it is. The greatest innovations and creations will come from small ideas. Experiences in various fields from machine design to new techniques in the artificial stone cement plast industry have come from these reckless ideas. For ideas, special forms can be arranged so that in every local form for the person's information, there are problems in the workplace, ways to fix it, suggestions, etc., and these forms are in places They put together various forms of the company and, at the end of each day, gathered information forms, and their expert review, though simple, seemed to be paying off.

Another way is to improve the efficiency of the Kaizen system. Kaizen has been gradually improving in all parts of the company and includes all individuals within a company from manager to employee and simple worker. The parts that have been selected for the analysis phase are the product depot, the amount of moisture in the aggregate, the wrapper (storage environment to product processing), waste, coordination for product delivery and production planning (and several suggestions in other areas).

Problems of aggregates in the production of flooring and mosaics cement plast:

Problems of aggregates in the production of flooring and mosaics cement plast:

The products of this artificial stone cement plast manufacturer were also multi-colored during this time (moisture content of rocks used in mosaics and flooring cement plast), especially in bright colors, after the examinations, the result was that the cause This is the wetting of the aggregates in the production of flooring cement plast.

On days when aggregates were freshly discharged, a larger percentage of the weight was formed by water, which meant that the amount of pencils in the material was less. In order to assure the researcher's claim, a certain volume of aggregates was weighed on that day, and this was repeated several times and the mean was obtained.

This work was carried out in 7 consecutive days and it was observed that after 3 days the aggregate was at a constant moisture content (due to the evaporation and evaporation of the aggregates used in the production of flooring).

Also, the company involved in the production of artificial stone had a problem with the transportation of aggregates (due to the traditional use of workers in the loading of raw materials), so that every day between 3 and 4 hours (according to the amount of production), one person should put aggregates up to the device Carry on by dumper.

Process of working in the warehouse of manufactured products (Artificial Stone Cement Plast):

Since the products made of artificial stone are very diverse (in terms of size, color, design and quality), the storage of the product in this unit is somewhat difficult. Products from the outlet The Shrink Pack device is shipped by a worker to empty spaces inside the warehouse.

Problems in the warehouse of artificial stone cement plast products:

Since the variety of artificial stone products is high, so the layout of the products was very disrupted and disorderly.

Lack of ventilation system in the warehouse of artificial stone products

The boundary between the various products of artificial stone (flooring and facade) is not clear (no special space was intended for the product)

An artificial stone warehouse cleaning was not optimal. In the warehouse of products, broken mosaics, worn pallets, torn cartons and ... can be seen.

Transportation inside the barn is very high.

Unemployment and time wasting of manpower are high.

Input products come from the packaging section, in different colors and designs, which makes transportation in the warehouse a lot, and creates a mistake in product placement.

There are half-full pallets of a type of product

The presence of artificial stone products and faucet near the entrance door that has become bustling.

A very small amount of light inside an artificial stone warehouse that darkens the storage space and uses artificial light even in the day.

Waste problems of the company producing artificial stone cement plast:

According to the findings, the waste was too common for the company and this would be a disaster. According to a survey of lesions, there were several reasons for the loss:

The molds were flat and broken before the material was filled.

Inside the floor molds and facade, the artificial stone was painted and the product was colored (dirty templates).

The product was perforated (the product had surface cavities or so-called mucus).

After leaving the product after a period of time required to maintain the treatment, it was filled with lips and broke corners.

On the products of artificial stone, dandruff was observed.

Coordination problems for shipping and shipping products to customers:

Produced products are packaged, and in stock depot products. But the coordination between sales offices and buyers was weak and the two parties were not in contact with each other. for this reason, (because of the transportation of goods in a lot of time), the packaging of flooring products and facades cement plast are soiled, or when they remain in the warehouse of unnecessary products and displacements due to lack of storage in the specified space, Products were damaged, or sometimes flooring and facades products were fractured at the time of product decompression due to the high pressure caused by the loading of the product.

Artificial Stone Cement Plast Production Planning Problems:

Orders and production of the product were made according to customers' demand and demand, but the precautionary reserve for all kinds of artificial stone and flooring cement plast intended for production was considered to be more than the required amount, which caused the production overload Mostly, due to the high availability of products in the warehouse, they are defective and grade 2.

Provision of solutions for problems of aggregates in stone and cement plast flooring production:

The first solution: the proposal of the researcher for the same example, as well as the shortening of the time of transportation, is the purchase of a Gardener tractor 254 and the front loader on it.

With the purchase of this machine, the length of the load will drop sharply. It can also be made smaller by aggregates, so that it can get evenly ahead.

Second Solution: The next suggestion by the researcher to solve this problem is to enlarge the aggregate depot space and make a 5 to 7 aggregate service in that space. This amount of these aggregates is about one month of production of a set of automatic artificial stone cement plast production lines. The gravel consumption of the first inlet will be. Thus, each grinding service will have a deadline of up to 15 days to eliminate their excess moisture.

Provide solutions for warehouse problems of artificial stone cement plast:

The refiner's suggestion is to use the Kaizen system to improve the storage situation, which requires the implementation of the 5S. Also, the segmentation of the warehouse and the determination of the geographical location for the parts and the affixing of the carton on the wall of each piece, on the card index, is the name of each piece. These pieces were designed in 4 different sizes. The A series, which is 8, is 2 square meters, the B series is 12, 25 square meters, the C series, which is 3, is 5 square meters, and finally the piece D is 20 square meters. In the piece A and B, the customer's custom products Placed. In item C, inventory is stored, and in item D load is loaded grade 2 and 3. When production planning is done for orders, depending on the size of the customer order, the type of piece is also determined (allocating sufficient space to each of the current orders).

Also, it should be noted that orders are less close to the exit door (loading door) and orders that are larger in size and need more time to be placed in the middle of the hall to avoid fragmentation and the dilemma of space.

The researcher's suggestion for low-lumen storage was the use of natural sunlight in the halls by putting glass or a shadow over the ceiling in place of Iranians, and also the use of lights at lower altitudes gave rise to light. The coloration of cement walls in white also provides much better indoor salon coverage.

5S system

Before explaining about 5S and its implementation, we would like to remark that these techniques can be implemented in all parts of the factory in addition to the product warehouse. 5S is the beginning of a safe / comfortable life for everyone in the workplace.

The driving force behind the implementation of 5S has come from within itself, and therefore shitsuke is a critical factor for success. Shitsuke needs to train people in order to lead them to follow good habits. Today, 5S has found countless supporters as a productivity improvement program.

Seiri:

Organizing irregular objects.

Discard and exclude unnecessary items and materials.

Payment and processing.

Seiton:

It means arranging and arranging objects in a particular order.

Seiso:

That is, cleaning the workplace in a manner in which there is no dust on the floor of the rooms and halls / machinery and equipment.

Seiketsu:

Maintaining the workplace in a manner that can be easily and efficiently replicated with seiro daily stando / seiton.

Shitsu:

Teach people to follow good business habits and strictly enforce workplace laws.

Reasons for implementing 5S:

The Kaizen program is relatively easy for beginners.

Everyone loves working environment cleanly.

The fruits of the effort are considerable for everyone.

More effective space is created.

Search time decreases.

The intervals are shorter.

The life span of cars and equipment increases.

The workplace becomes a safe and secure place.

The error and mistake are less likely to happen.

All people are self-disciplined.

The capital of the program is small.

Consumers will be satisfied.

The company's reputation increases and employees feel proud of the regular work environment.

The overall efficiency of the company's personnel will increase.

To run 5S, consider the following points:

Awareness of the highest executive officer of the organization with this technique (it is desirable to visit the sample companies that have applied the 5S program and take into account the results of the success).

Understand 5S as a comprehensive productivity improvement program to run across the company.

Seiri implementation in the warehouse: There are floorboards that are stored as lost sales. Given the step of a 5S, we have to expose these items immediately. Torn cartons and all waste material are discarded and space is used more specifically (space means money). Flooring and shots that are more exposed to sales are located in the doors of the entrance door and other products in priority order in faraway locations.

How to implement the s5 technique in the company:

Create an effective service space by removing unnecessary objects and sorting out the remaining items and supplies each month.

For example, on days where, for example, there are eight numbers on that day. (E.g. eighth / eighteenth and eighth month each month)

Take two days of the year as a big grooming day. The day of big grooming should be organized two days a year on a regular basis. (A person in charge of large cleaning should design a detailed program using the 1h and 5w method (who / what / where / when / whom / how).

On a daily grooming day, all employees have to stop working and focus their attention on cleaning. Interior and exterior walls / ceilings / windows / floors / corridors as well as machines and equipment / office machines / fixtures should be completely cleaned up to shine. The exterior of the building, including car parks / guard posts / gardens / waterways and passageways, should also be cleaned.

Divide the company environment into small areas and assign small groups of individuals to each area. We can use the idle time for workers to run 5s.

Waste and waste classification that can be classified into six categories:

Disadvantages caused by excess production.

Defective waste.

Waste due to delay and waiting time.

Waste caused by accumulation of materials during production stages.

Transport losses.

Waste caused by unnecessary actions and activities.

If we analyze the precise and complete source of such waste classification, we will be able to reduce costs and increase productivity.

Being punctual / clean and tidy / respecting safety regulations / working team spirit and good ethics in the company.

For each device (or a set of multiple machines depending on the work situation and conditions), we determine the authorities. (Use of excess time to run steps)

Alternatively, donate prizes to the groups and people who practice the 5S practice correctly.

Visit surveys from other 5S executives to provide the necessary backgrounds to help implement the reforms by exchanging ideas and views.

Providing solutions to some of the waste of the company producing artificial stone cement plast:

The researcher's suggestion to resolve this problem is to determine the responsibility for the template section so that it disconnects the broken templates at the start of the work, and again announces the statistics of existing templates, and checks the templates at the end of each day, and in If needed, rinse colored molds.