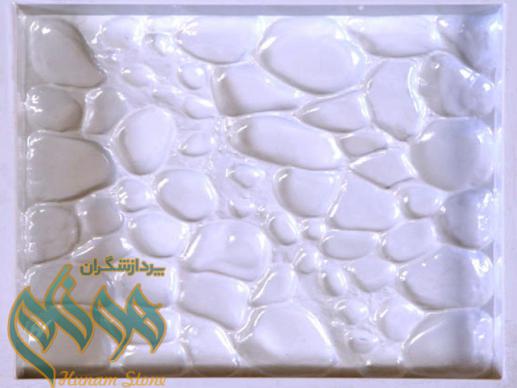

mold of artificial stone cement plast

Artificial stone molds are the main pillars of artificial stone production. Artificial stone molds are divided into two general categories: hard molds and soft molds.

Soft molds are used to produce decorative stone facade, including rubber molds, PVC, silicon and polyurethane.

Which are mainly used for the production of flooring and antique mosaics, stairs, under stairs, tables, etc., also, other types of molds are HP molds that are similar to ABS molds and for facade and decorative products with adobe surface and low positive and negative angles and Matt are used.

the genus of artificial stone cement plast molds | public molds to produce artificial stone | of what?

In this technology (artificial stone nano cement plast), generally used molds of the so-called dry type are used. soft molds in this technology can only be used to produce facades, this is due to the fact that the ready-made dry molds are not available, to produce glossy products, you should use dry ABS molds. in facade products, soft molds can be used, because they are generally matt, but we need to consider the requirements in Vibrations. depending on the nature of the product (flooring or facade) and the glossiness or opaque (due to the percentage of gloss or opaque of the product), the following types of genders are used for production.

1.ABS

2.HP (PS) The first case is for glossy molds and generally flooring (mosaics) and stairs and tables, And, in general, for all products that require superficial gloss, is used

The first case is for glossy molds and generally flooring (mosaics) and stairs and tables, And, in general, for all products that require superficial gloss, is used

The second case for molds with matt appearance (not gloss) and generally for products such as artificial stone facade, is used

How long is the shelf life of each artificial stone cement plast mold?

Generally, flooring molds and glossy will be used between 300 and 1000 production times (Total production) between one to three years of work

Generally matt molds (facades) Between 180 and 500 Multiplication (Total production) are used

But the useful life of the molds depends on factors such as the thickness and quality of the sheet used, negative and positive angles, the proportion between width & length and thickness of the product and... are affiliated Injectable molds are better for artificial stone cement plast production or forming molds?

Injectable molds are better for artificial stone cement plast production or forming molds?

Only forming molds are used in artificial stone cement plast technology. it is true that injectable molds have a longer shelf life than vacuum forming molds, but due to injection of materials into these molds, and the creation of tiny microscopic lint, the adhesion of the material takes place in the mold and the products produced with these molds (injection molds) are considered as waste.

forming molds due to surface integrity are not included. also due to the smooth surface of the forming mold, the polish and glossiness of the product are much more in these molds.

Is it necessary to heat the molds to remove the stones produced from the molds?

No, product with vibration or soft impact can easily be removed from the mold and there is no need for heat. in the event of inappropriate heat and maintenance, the templates lose their original shape or become deformed

What are the materials used to rinse the molds?

For the purpose of washing the mold, to change the color of the manufactured product, use chloride acid

Can we also rinse the molds with gasoline?

No, gasoline is a solvent of molds, especially glossy molds, and if you use gasoline to clean the molds, the molds will be damaged.

Can designing new designs?

This will be possible in molding, due to some minor constraints, designing and molding various designs of artificial stone, inscriptions, etc. in very large sizes (2 m wide and 3 m long). but this design requires the presence of experienced people. in some cases, due to the impossibility of making some artificial stone designs, with negative and positive angles ... it is necessary to use soft rubber molds produced by some companies or silicon molds and PVC molds. keep in mind that this is the type and form of the molds, which determines the type of impact. therefore, if the molds are dry, the vibration table should be vertical and if the molds are soft, then the vibration table should be horizontal. in the training sessions, we will talk about how to create horizontal or vertical blows at the vibration tables.

But in vibration tables with a small width and high length or vibration tables with an electro motor, the blows are only horizontal. this is very important, and investors who do not pay attention to these items will suffer losses.